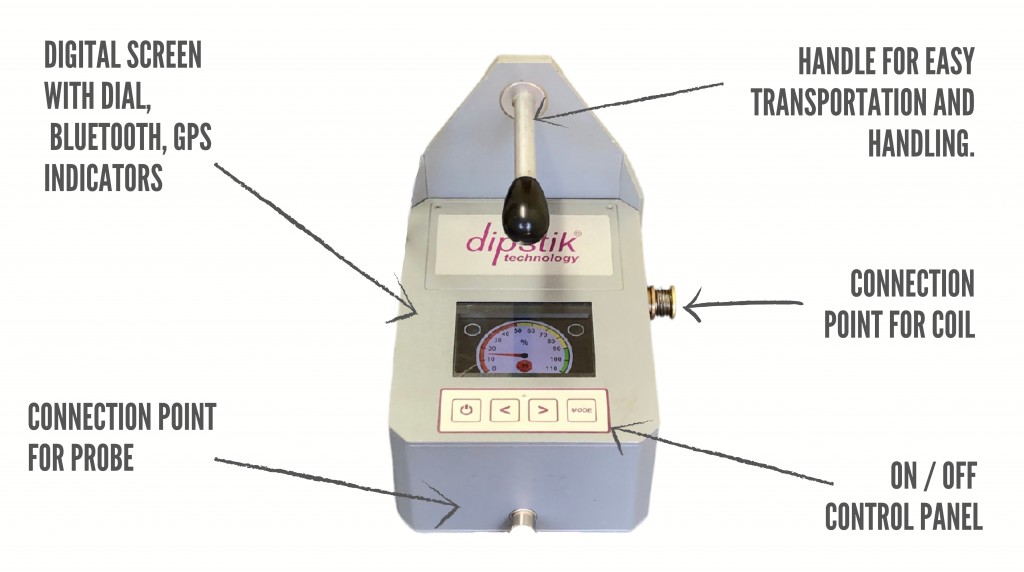

Model C Dipstik®

New Features

The new model ‘C’ dipstik brings a level of automation and increased reliability to our testing.

Click on the features below to find out more.

Testimonials

Dipstik® technology was developed by Alan Hobbs, a retired SAP (Senior Authorised Person) with London Electricity. Through his work with local authorities electrically testing columns, as part of the Electricity at Work Regulation requirements, Alan came up with the idea for Dipstik ® Technology. Local authorities had no recognised way of determining whether columns were fit for purpose.

Dipstik® technology was developed by Alan Hobbs, a retired SAP (Senior Authorised Person) with London Electricity. Through his work with local authorities electrically testing columns, as part of the Electricity at Work Regulation requirements, Alan came up with the idea for Dipstik ® Technology. Local authorities had no recognised way of determining whether columns were fit for purpose.

The dipstik® solved the problem that duty holders had of testing columns that were difficult to access with other test methods.

It provided reliable and proven results that came from the oil and nuclear industries where cracks and defects in shafts could go undetected. The dipstik® was able to replicate this method and provide a clear picture of the degradation of column material above and most importantly, below ground where corrosion cannot be seen.

To date, Dipstik® technology has found hundreds of corroded columns and is used on over half a million columns a year, across the UK.

Failed Columns

The benefit of Dipstik ® Technology, is that it can locate a loss in column thickness below ground, without the need for costly excavation, however, sometimes severe corrosion can occur in plain site but requires the Dipstik® to identify it. Click below to see examples.

Mark Johnson

Mark Johnson Richard Webster

Richard Webster Sue Kinsella

Sue Kinsella